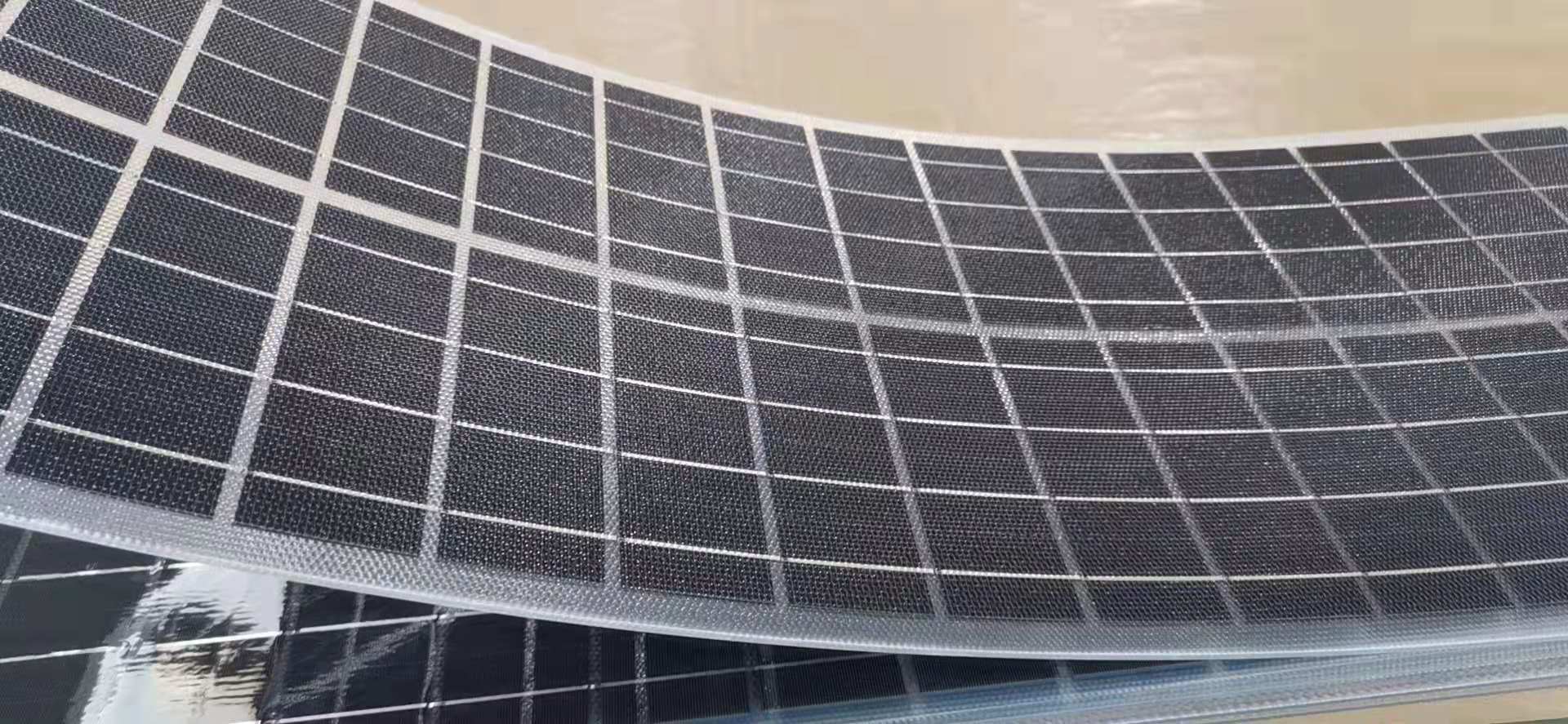

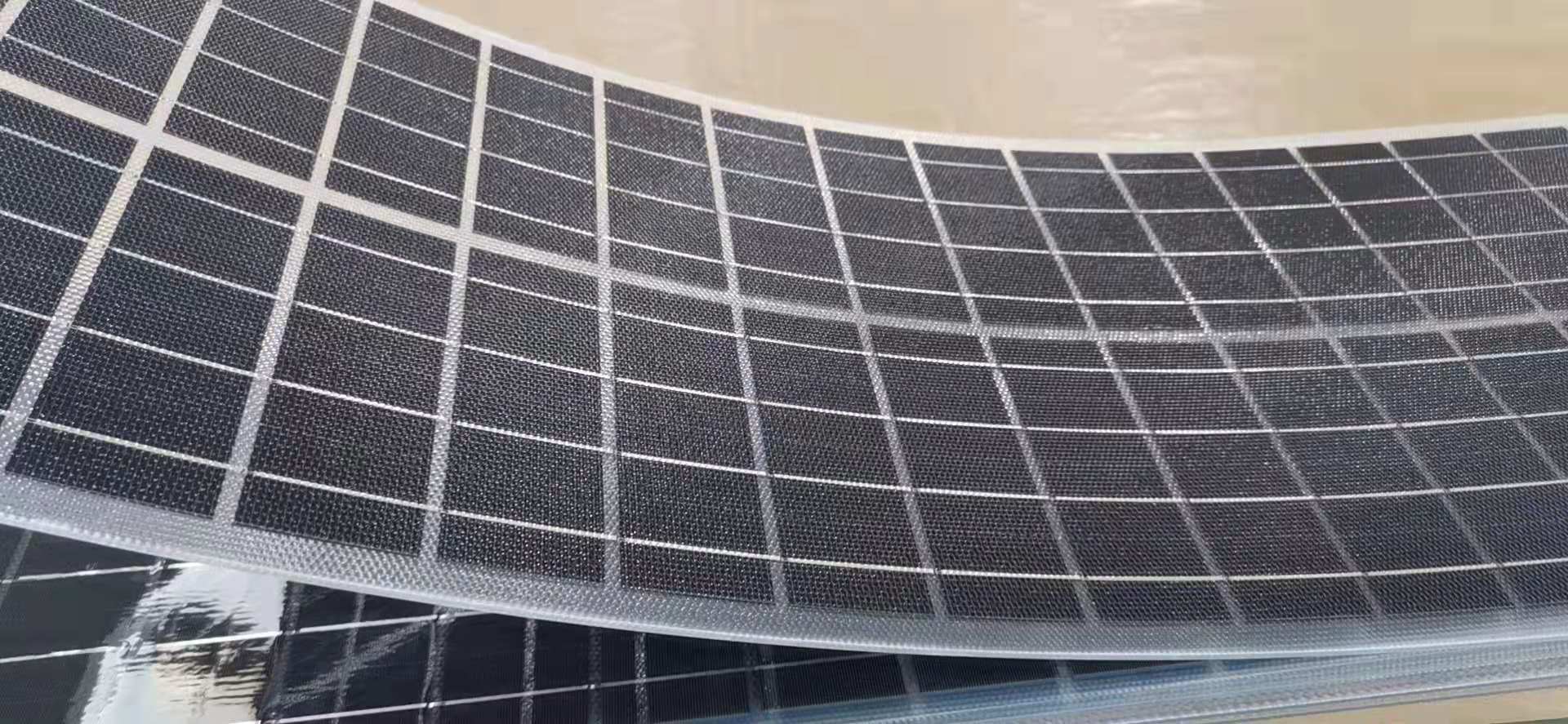

Bifacial transparent Flexible ETFE solar panel

Customized Flexible solar panel with ETFE lamination.

Monocrystalline bifacial solar cell, High efficiency transfer.

Transparent backsheet, to make use of solar energy, a good replacement of transparent glass solar panel.

Benefits of ETFE

Excellent light transmittance-ETFE film can be highly transparent and allows ultraviolet rays to pass through. Ultraviolet rays are responsible for promoting photosynthesis, thereby promoting plant growth.

Solar control/shading-ETFE thin film system can add a variety of glass frit patterns on one or more layers to change its solar performance. The foil is printed with various standard or customized patterns. Color can be introduced in various ways, whether it is applied during the film extrusion process, providing consistent hues of various shades from red to purple, or adding lighting with unlimited color options.

Elasticity-Although ETFE films are very elastic, they are still structurally resistant. The tensile strength at the elastic/plastic limit is 21-23N/mm2, but the tensile strength at the breaking point is 52/Nmm2. For membrane structure calculations, the limit of 15 N/mm is usually conservatively adopted.

Durable-ETFE will not degrade after long-term exposure to environmental pollution, ultraviolet rays, irritating chemicals or extreme temperature changes.

Acoustics-ETFE film has approximately 70% acoustic transmission

Sustainability/Energy Saving-From film extrusion to transportation to the site, compared with other similar coating materials, it consumes very little energy, thereby reducing the overall carbon footprint. In addition, the nature of the product enhances building physics through heat insulation and daylighting, thereby contributing to the global low energy consumption of buildings.

Cost-effectiveness-Due to the lightweight nature of ETFE, the substructure support system and concrete foundation can be designed more effectively. The ETFE system also provides sufficient natural lighting, thereby minimizing energy costs by reducing the need for indoor lighting.

Recyclable-easy to recycle, waste from the manufacturing process and even old ETFE components can be remade into new ETFE products, such as pipe parts, wires or castings.